Aluminum silicon copper alloy - EN AB 46400

ALUMINIUM ALLOY GAlSi9Cu1

Like GAlSi9, it is a very suitable alloy for making massive parts or parts with high thermal stress.

Compared with its “bigger” relatives GAlSi9, GAlSi9Cu1, thanks to copper, has better heat dissipation, a slight self-tempering effect, and therefore ready to work even without heat treatment.

Its relevant characteristic is its ability to give rise to well compacted masses and an extremely fine and homogeneous grain, which allows the achievement of superior quality processing and or the possibility of receiving treatments of Chrome Plating, Nickel Plating, Nicasil carryover, etc.

However, T6 heat treatment is possible and further improves the properties.

Areas of Application

AREAS IN WHICH ALUMINUM ALLOY GAlSi9Cu1 IS USED.

Appliance

-

Grids

-

Cappellotti

-

Knobs

-

Burners

-

Wok Supports

-

Tubs

OLEODYNAMIC Applications

-

Distributors

-

Shut-off valves

-

Control valves

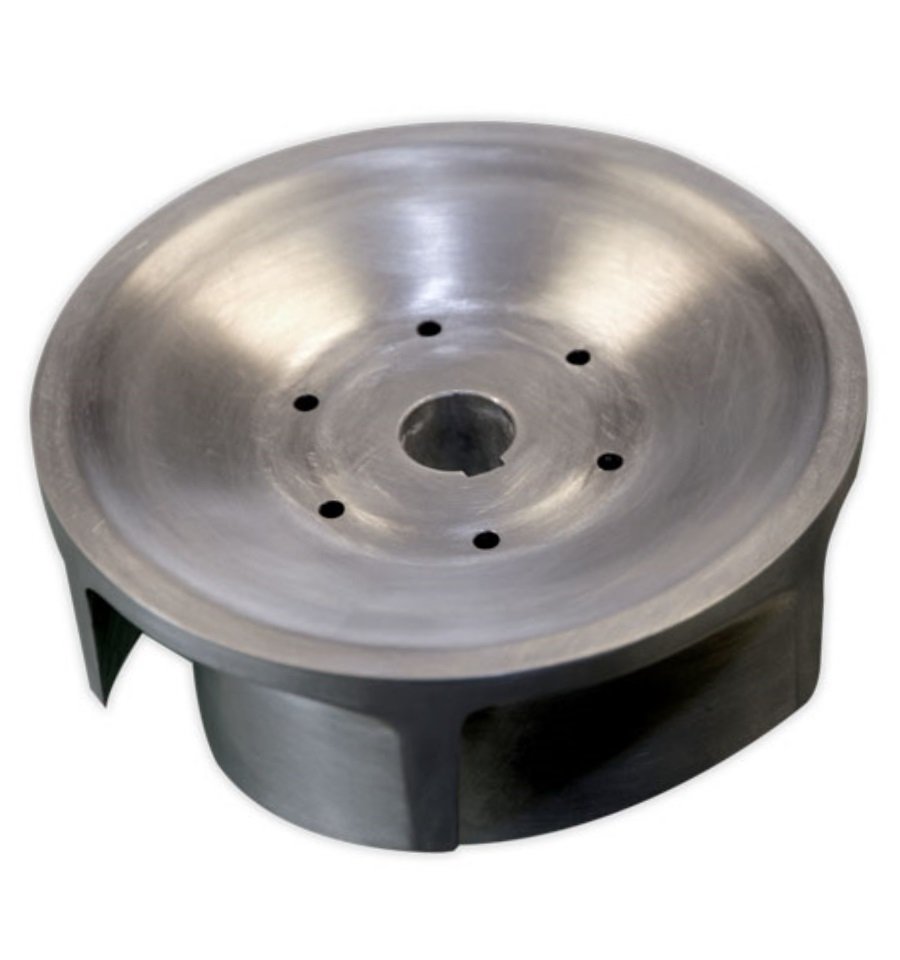

Construction of Pumps

-

Pump body

-

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Diffusers

-

Circulators

-

Supports

Automotive

-

Racing Components

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks

Electromechanics

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights

ALUMINIUM GAlSi9Cu1

| Elem. | % Min | % Max |

|---|---|---|

| Si | 8,3 | 9,7 |

| Fe | 0 | 0,7 |

| Cu | 0,8 | 1,3 |

| Mn | 0,15 | 0,55 |

| Mg | 0,30 | 0,65 |

| Cr | - | |

| Ni | 0,20 | |

| Zn | 0,8 | |

| Pb | 0,10 | |

| Sn | 0,10 | |

| Ti | 0,10 | 0,18 |

| Individual impurities | 0,05 | |

| Global impurities | 0,25 |

NB: Data subject to change among the various foundries

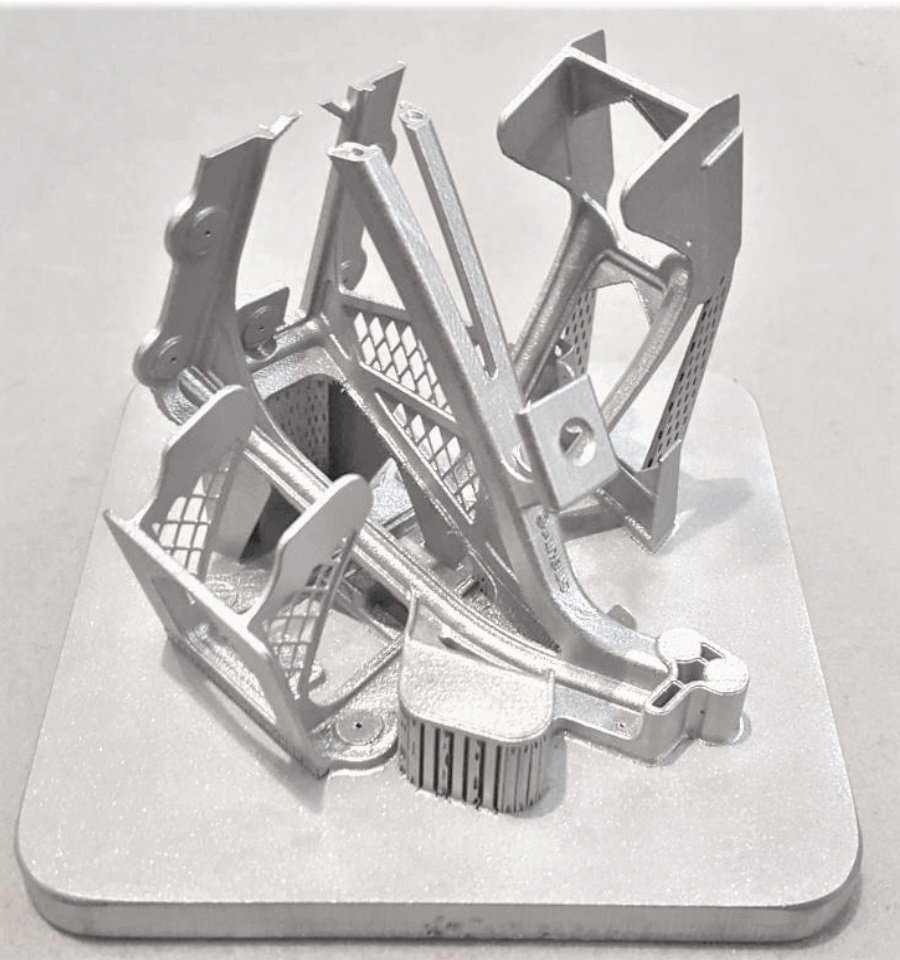

Prototype creations in aluminum

Some of the prototypes we made in aluminum alloy

LARGE COMPANIES

WHO HAVE CHOSEN US