Rapid Prototyping

- Home

- Rapid Prototyping

All our rapid prototyping solutions:

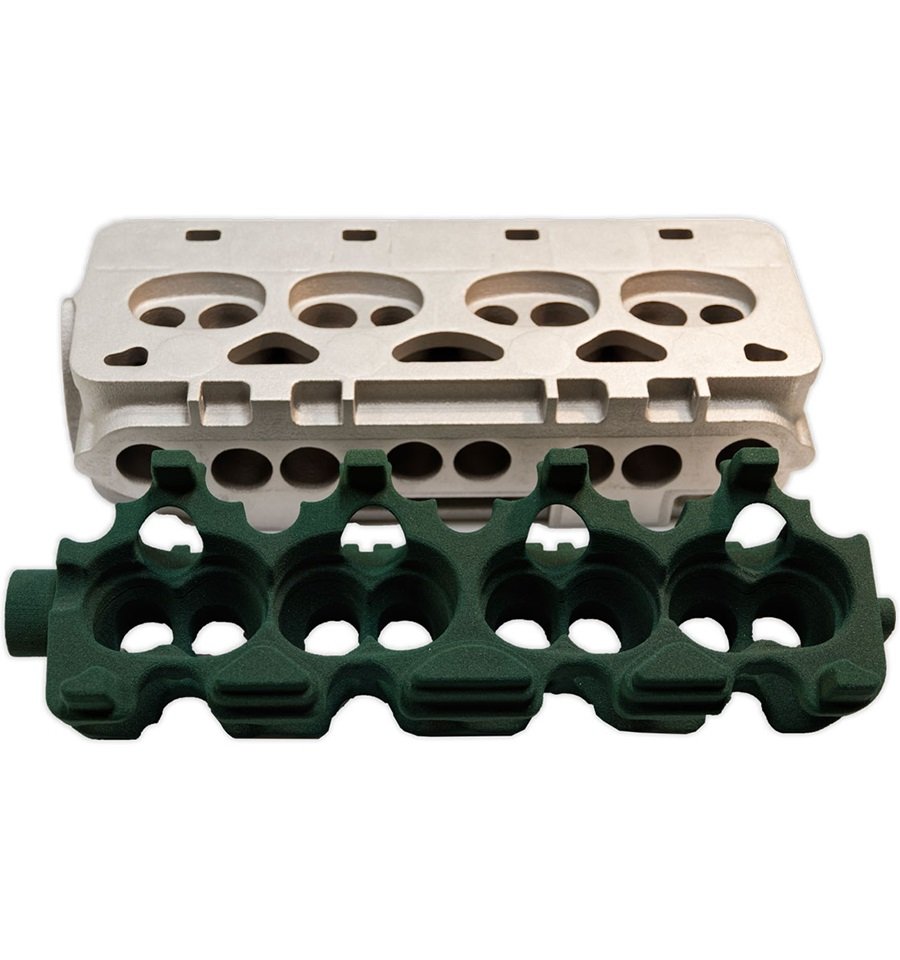

3D Molds Printing

With 3D printing solutions, we can make digital core "prints" directly from 3D STL files.

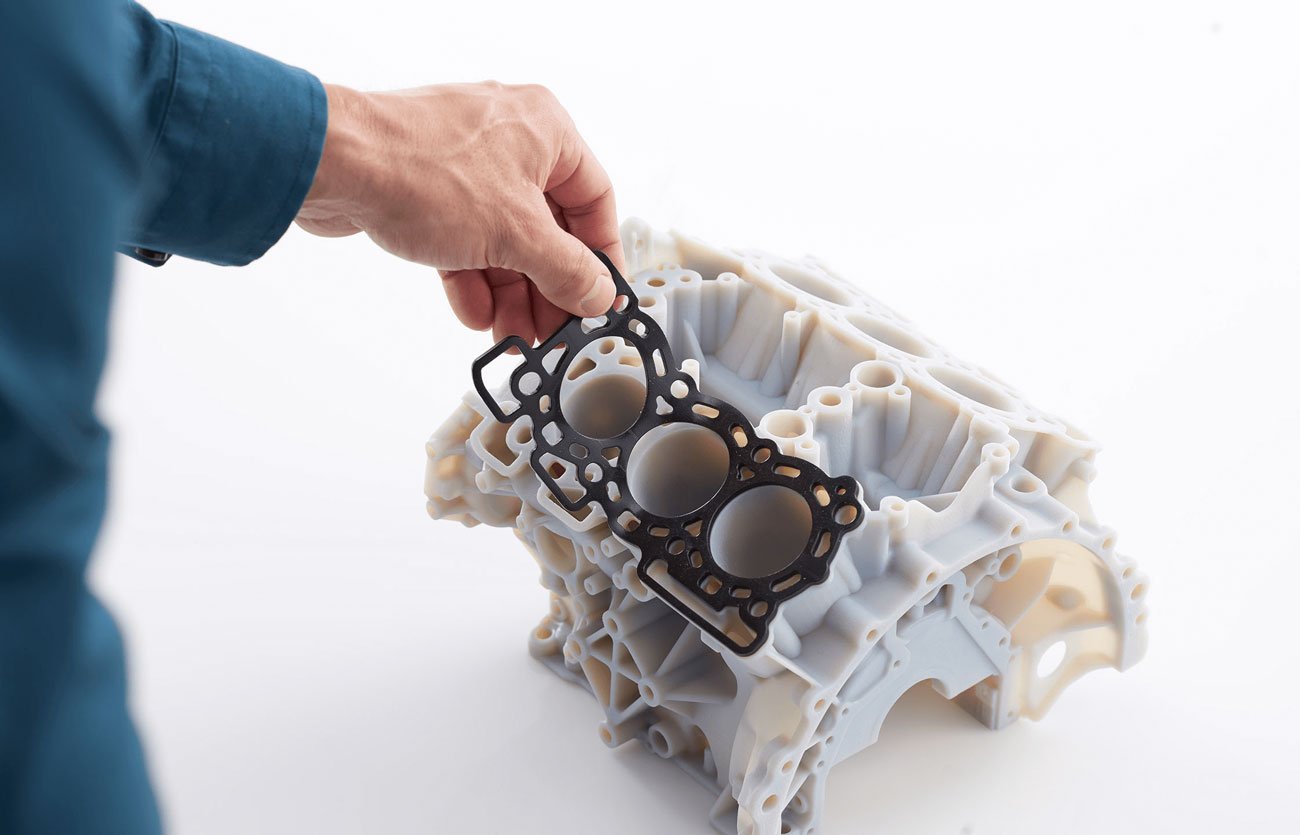

Quick Sand Casting

Quick Sand Casting is the rapid casting prototyping technique by which real metal castings are made.

SLS Printing

SLS printing is the rapid prototyping technique that uses the construction material in powder form Polyamide-based plastic powders even with 30% fillers.

DMLS Printing

Direct metal laser sintering (using metal powders), also known as DMLS, is a rapid prototyping technique of direct construction of prototypes obtained from 3D files.

Stereolithography

Stereolithography is a rapid prototyping technique that allows the construction of parts by selective addition of material in liquid form in a tank.

Object

Object solutions make it possible to simulate rigid plastics, both opaque and transparent, or rubbers in different hardnesses.

Microfusion and waxes

Investment casting, also known as lost-wax casting, employs sacrificial models identical to the geometries of the part to be produced in metal.

CNC Milling

By means of CNC milling, objects in a wide variety of materials can be constructed from a block of the chosen material and shaped by milling machines.

Silicone printing

Prototyping with Silicone Molds is a micro-manufacturing technique called "soft tooling" since the mold is made of precisely soft material.

Surface Finishes

On request we carry out technical finishing treatments of prototypes, especially for those made of plastic materials

Carbon lamination

In addition to the ability to make nylon prototypes with carbon fiber filler from 3D printing, we can also make high quality real carbon fiber objects.

Prototypes Services

With Rapid Prototyping services, we can make your designs real by producing functional parts in plastic, rubber, aluminum and cast iron in a very short time, reducing your “Time to Market” and enabling overall prototyping project cost containment.

3D CAD

Rapid Prototyping in metal and plastic

Reverse Engineering

Equipment construction

Castings supply

Mechanical design

Threedimensionalization

Parametric modeling

-

Grids

-

Caps

-

Knobs

-

Burners

-

Wok Supports

-

Tubs

-

Distributors

-

Shut-off valves

-

Control valves

-

Pump body

-

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Diffusers

-

Circulators

-

Supports

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights

-

Racing parts

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks