3D printed molds

- Home

- Rapid Prototyping

- 3D printed molds

Silica sand for 3D printing

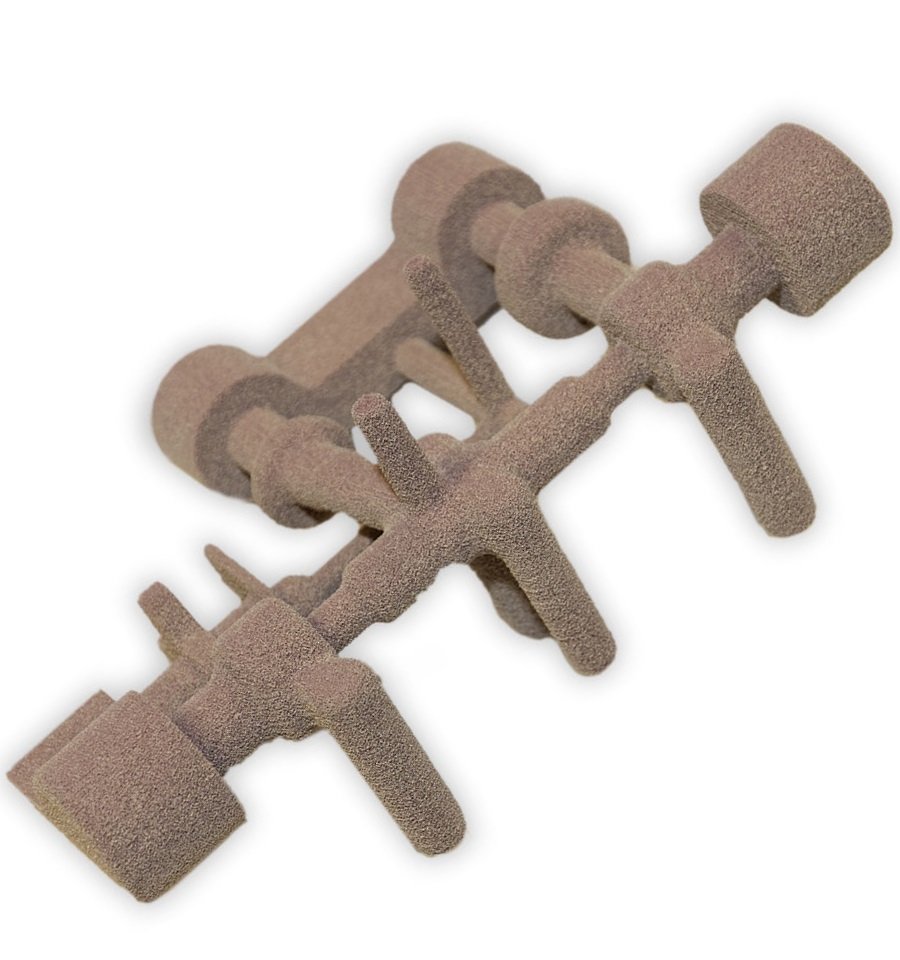

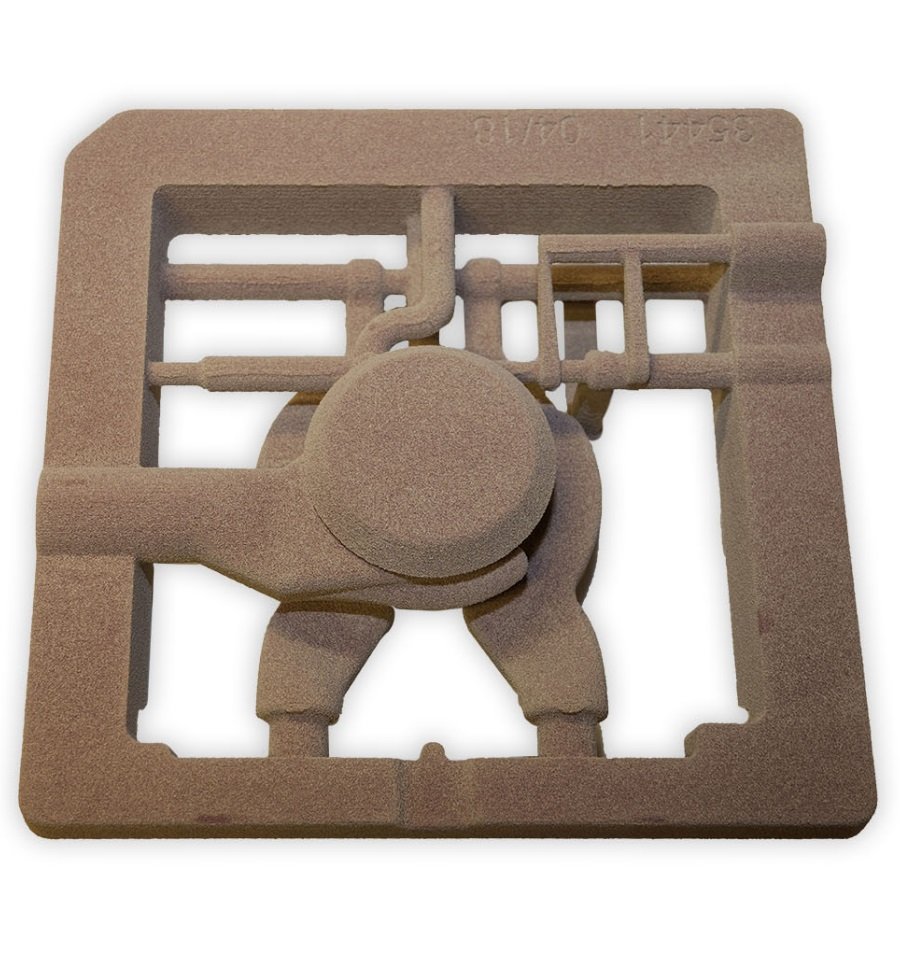

With 3D printing solutions, we can make “prints” of foundry molds directly from 3D STL files. These sacrificial parts are perfect for leaving complex cavities within metal castings made from the most common alloys of foundry aluminum, cast iron and others.

The technique allows the digital design of even very complex and slender figures obtained by progressive layering of inert material bound by a two-component resin system. The construction does not require supporting materials so you can make really elaborate figures or very complex groups that with other solutions would have to be separated into the individual figures then solved individually.

Foundry moulds from 3D printing

-

Based on silica sand and furan binder (identical to the “cold-box” product), they are perfectly compatible with all foundry processes for aluminum, cast iron, bronze and brass.

-

They allow complex shapes to be obtained in just a few days, without necessarily having to break down undercuts, modify outlines or study branching.

-

High detail, good strength, high permeability and minimal “LOI”.

-

The 1800x1000x700(h)mm printing area can comfortably accommodate your production needs, be they small core arrays or major monolithic assemblies in the form of pre-rolled cores.

-

Grids

-

Caps

-

Knobs

-

Burners

-

Wok Supports

-

Tubs

-

Distributors

-

Shut-off valves

-

Control valves

-

Pump body

-

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Diffusers

-

Circulators

-

Supports

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights

-

Racing parts

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks