Sand for 3D printing

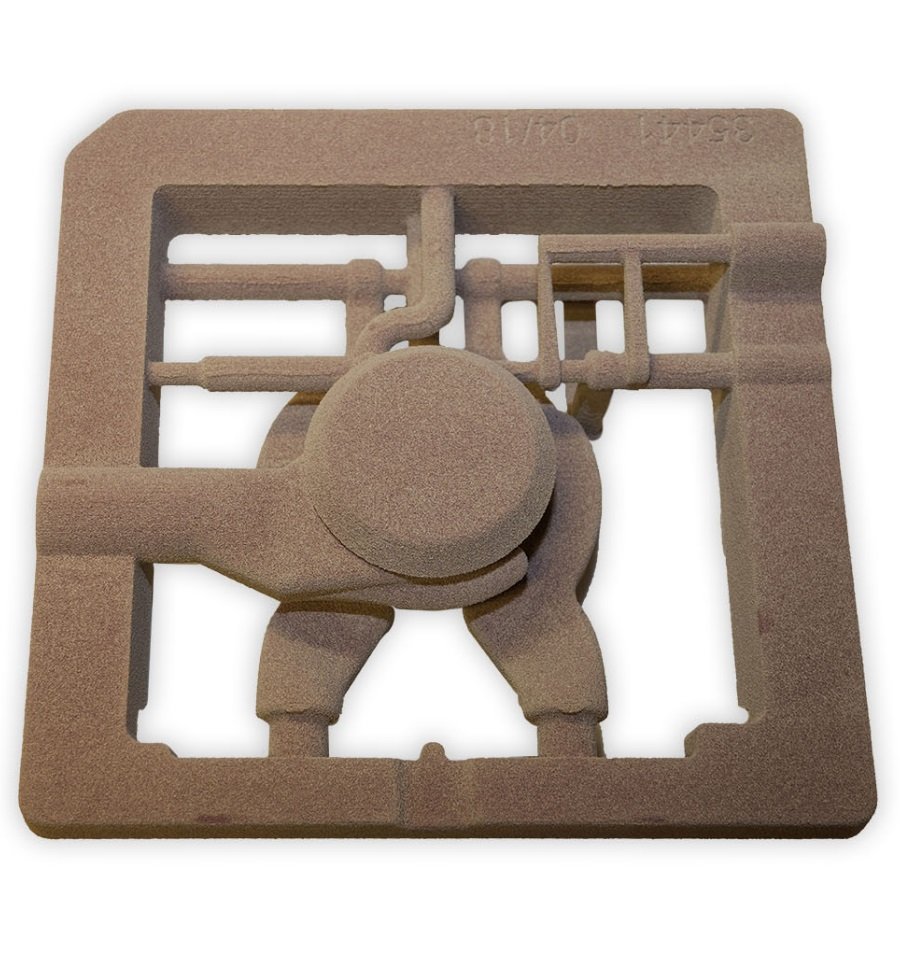

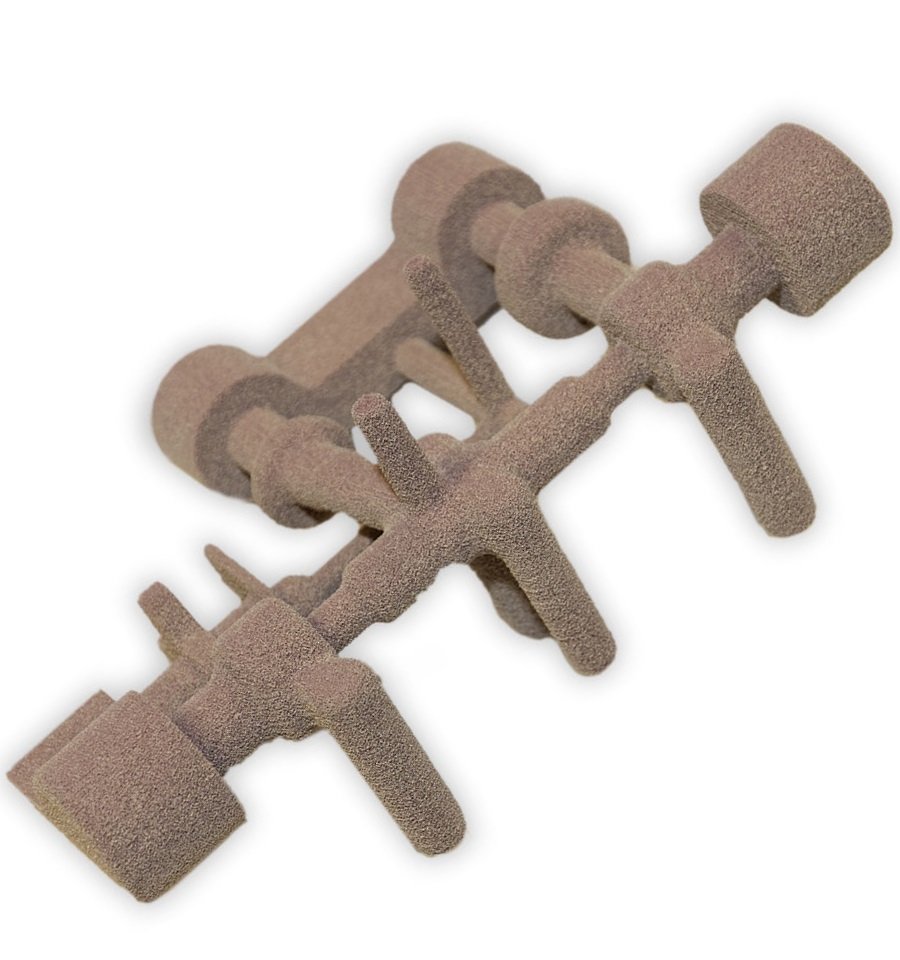

Prototypes from prototype cores and Quick Sand Casting

Silica sand (silica or Cerabeads) is used in 3D printing of prototype cores, or used as a semifinished product also for Quick Sand Casting processing, in which, however, the semifinished product is assembled and then taken to the foundry to convert the mold into a metal part. The machine prints a figure that is directly delivered to the customer. The figure is always obtained with a “powder,” silica sand to be exact.

For foundries or molding shops that require smoother, more finished parts specifically for hydraulic or oleodynamic uses, cores are treated with specific coatings based on zirconium, graphite, aluminosilicate or other.

3D PRINTING with Silica Sand from Resin

Silica sand is bonded through a resin using a 3D printing process similar to plotting. Layer by layer, an even very complex shape is created, which is technically called 2.5D, the material replica of the 3D file sent by the customer.

2.5D is the acronym for identifying an object reproduced by printing an N number of finite layers that make up the Z height dimension. Since they are infinitesimal, the plotting measurements in X and Y represent 2 complete dimensions, while since Z consists of a finite number of layers (or layers) with a finite and fixed thickness for each layer, the Z dimension thus created is counted as 0.5. There is currently no solution that allows infinitesimal growth of Z.

For prototype cores, the layer thickness or layer thickness is 280 microns.

-

Grids

-

Cappellotti

-

Knobs

-

Burners

-

Wok Supports

-

Bathtubs

-

Distributors

-

Shut-off valves

-

Control valves

-

Pump body

-

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Speakers

-

Circulators

-

Supports

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights

-

Racing Components

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks