Prototypes from Quick Sand Casting

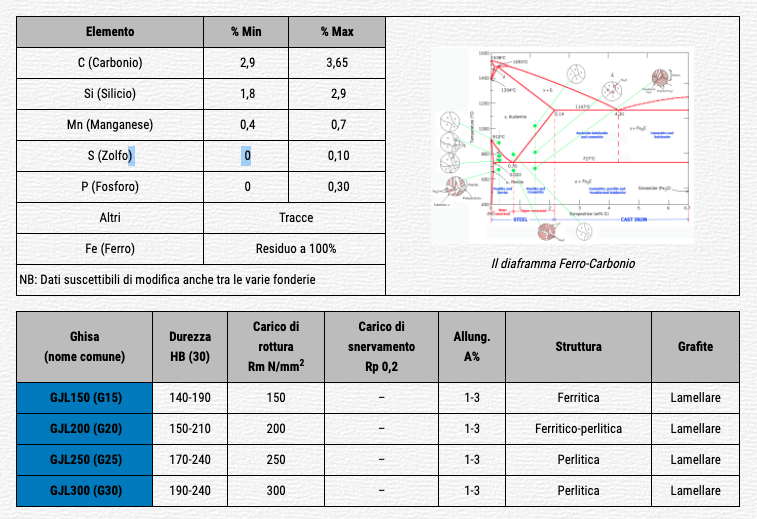

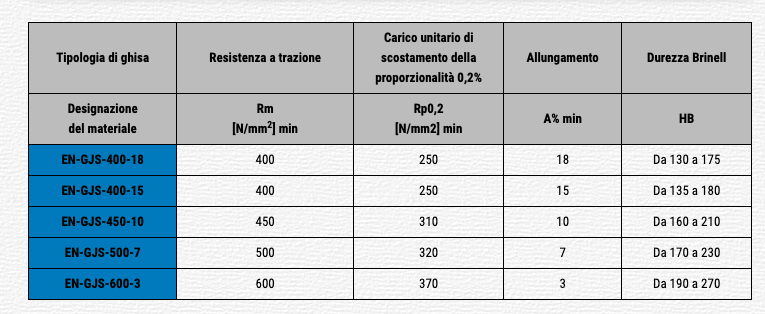

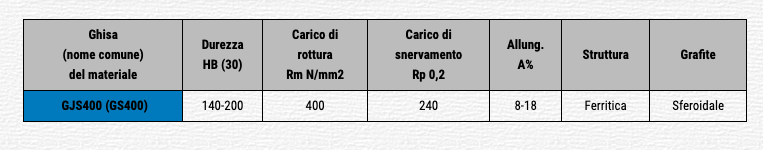

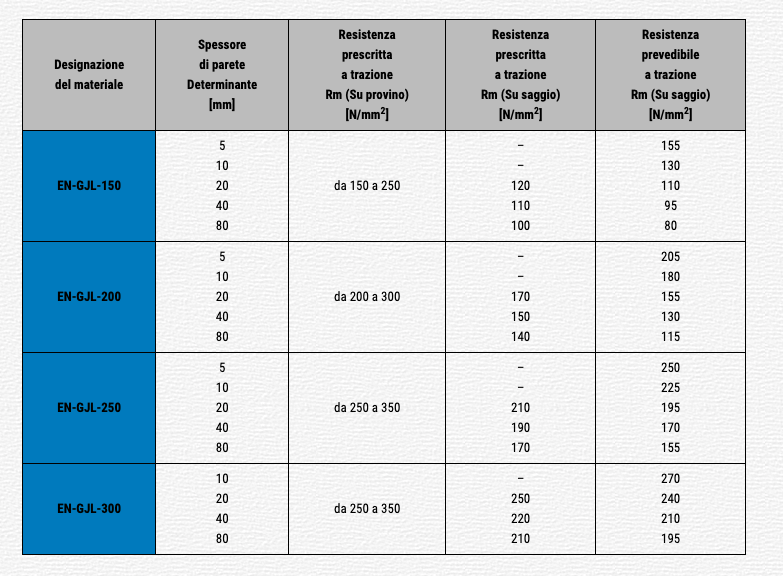

The values actually found on a casting depend strongly on the thickness of the element considered and the morphology of the casting: these two aspects jointly determine the cooling curves and thus the set of mechanical characteristics for functional prototypes.

In prototyping, the combination of material and processing technique is one of the most complex choices. Running a prototype almost always requires evaluations so, for the use and consumption of engineers, average material properties obtained by prototype construction are provided. These can be used to get an idea of technical and functional compliance.

Gray cast iron microstructure: crack propagation within gray cast iron. The crack wedges into the graphite (present in foil form) and propagates.

Spheroidal cast iron microstructure: crack propagation within spheroidal cast iron. The crack wedges into the graphite (present in spheroid form) and is arrested.

The above data are intended as a guideline since they can be found only on standard specimens cast automatically on in-ground molding equipment. The values actually found on a casting depend strongly on the thickness of the element under consideration and the morphology of the casting (in fact, these two aspects jointly determine the cooling curves and thus the set of mechanical characteristics).

As an example, it is shown how the breaking load varies as thickness varies:

-

Grids

-

Cappellotti

-

Knobs

-

Burners

-

Wok Supports

-

Bathtubs

-

Distributors

-

Shut-off valves

-

Control valves

-

Pump body

-

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Speakers

-

Circulators

-

Supports

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights

-

Racing Components

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks

In prototyping, the combination of material and processing technique is one of the most complex choices. Running a prototype almost always requires evaluations so, for the use and consumption of engineers, average material properties obtained by prototype construction are provided. These can be used to get an idea of technical and functional compliance.

Areas of Application

-

Grids

-

Cappellotti

-

Knobs

-

Burners

-

Wok Supports

-

Bathtubs

-

Distributors

-

Shut-off valves

-

Control valves

-

Pump body

-

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Speakers

-

Circulators

-

Supports

-

Racing Components

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights