Selective laser sintering

- Home

- Rapid Prototyping

- Selective laser sintering

SLS Printing

Plastic powders, rubbers, carbon

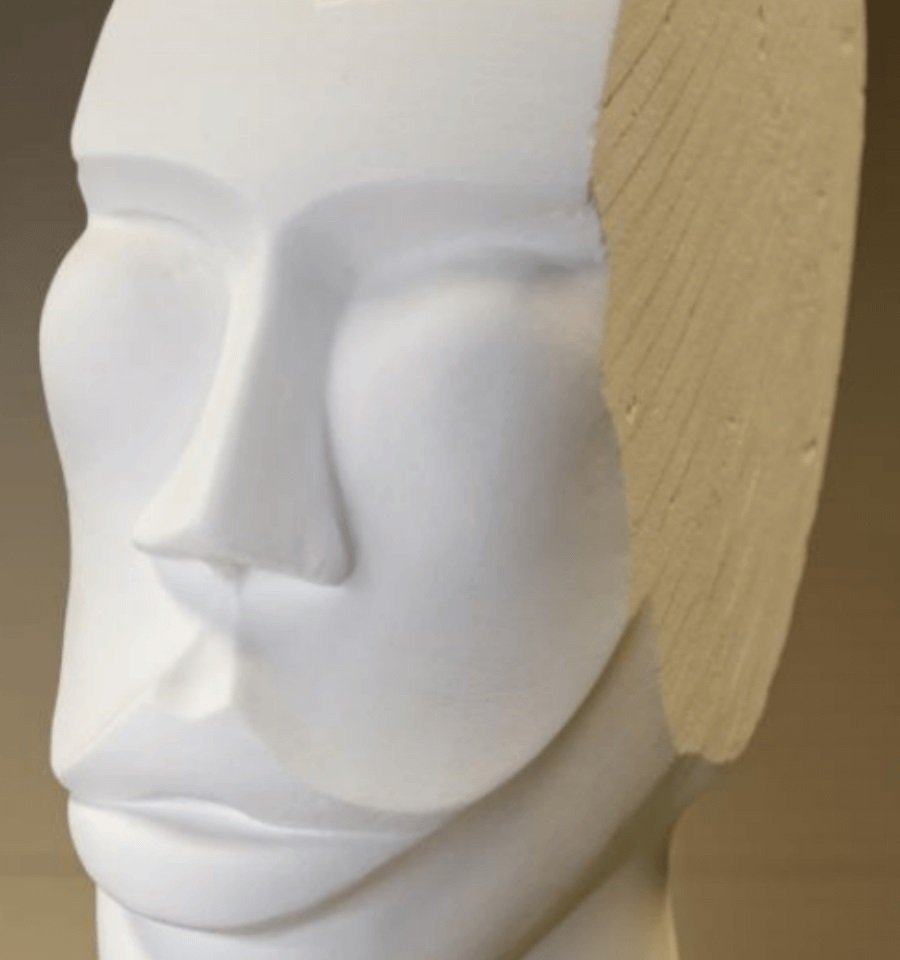

Selective Laser Sintering (SLS) is the rapid prototyping technique that uses Polyamide (PA)-based plastic powdered material also with 30% fillers (Glass or PA-GF filler, Aluminum or PA-AL/Alumide filler, Carbon or PA-C/Carbomide filler). Laser processing binds the grains together generating solid but not perfectly compact shapes,due to residual spaces between the grains that are never completely dissolved. To achieve compactness and ensure hydraulic tightness, parts made with SLS printing must be infiltrated or impregnated. Rubber-like objects can be made from SLS using rubber granules (polyether amide block or PEBA).

Taking advantage of structural assembly and bonding, our plastic sintered products have no real dimensional limits. Large objects can be broken down into smaller sub-parts that already have mechanical joints (dovetail type) that are reassembled with structural epoxies and finished with fiberglass fabric in order to ensure superior strength of the laser cutting area. Such strategies enable time and cost optimization as well as optimizing the inherent deformations in thermoplastics processing.

This solution is very suitable in all those testing applications where a detail aspect comes to compromise with the best feature of the industrial polymer.

Selective laser sintering

The material has a typical texture of industrial nylon, very tensile strength and less shear strength. The aluminum filler exhibits remarkable wear resistance.

-

The tikcness layer is 120 mm;

-

Plastic sintering machines with working range 700 x 580 x 380 mm (h) ideal for making high-strength and large plastic prototypes;

-

Plastic sintering machines with working range 330 x 330 x 600 mm (h) ideal for making plastic prototypes of good detail and very economical;

-

Ice white color (for PA and PA-GF); metalliscent gray color (PA-AL); dark gray color for the (PA-C);

-

Paintable by application of acrylic enamel.

-

Grids

-

Caps

-

Knobs

-

Burners

-

Wok Supports

-

Tubs

-

Distributors

-

Shut-off valves

-

Control valves

-

Pump body

-

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Diffusers

-

Circulators

-

Supports

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights

-

Racing parts

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks