Quick Sand Casting

- Home

- Rapid Prototyping

- Quick Sand Casting

Rapid Prototyping

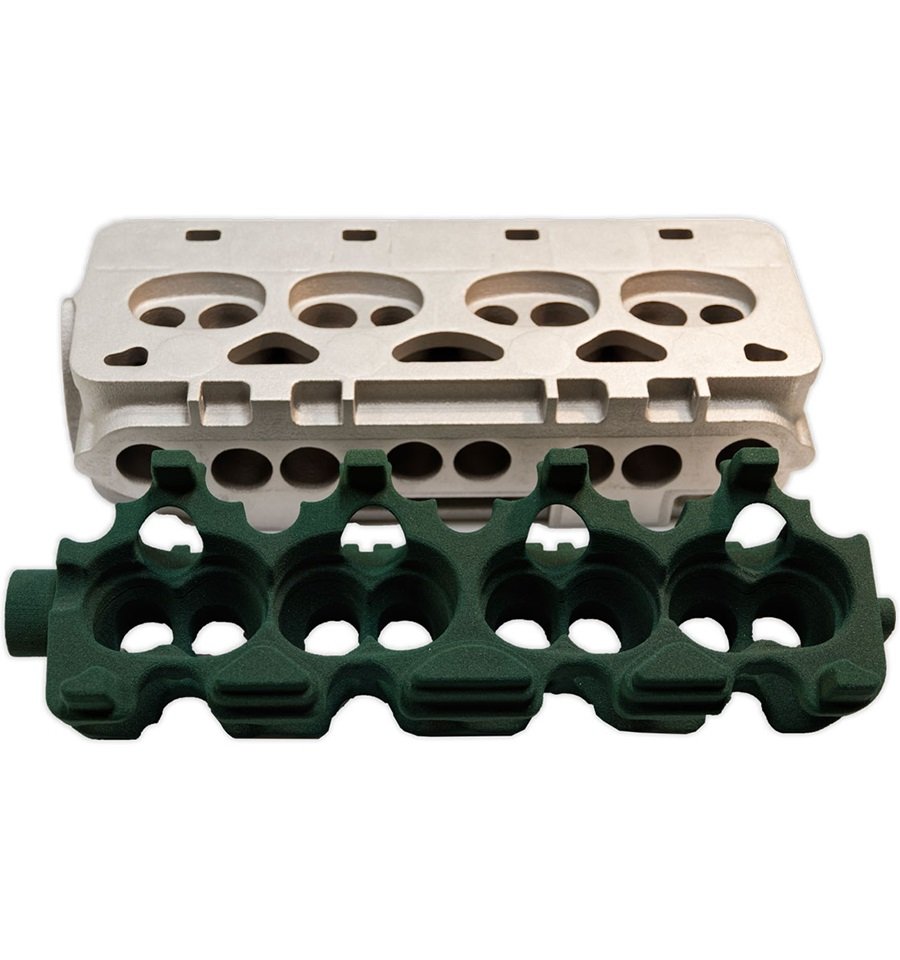

Quick Sand Casting is the Rapid Casting prototyping technique by which real metal castings are made, directly into the final alloy, obtained by classical foundry processes. This ensures the best replication of the mechanical characteristics of the prototypes that come to be fully preproduction objects.

This technique involves manipulating the 3-D model of the part to be produced in order to derive the design of a series of disposable pre-molds (motes) (made from sand and resin using prototype techniques) that will then be assembled and used for the actual casting of the cast alloy. The motes contain both the cable of the part to be made and the undercut or core elements.

Rapid casting: the advantages

- Exact replication of the mechanical characteristics of the prototypes

- Increased strength and lightness of replicas

- Ability to make mechanical parts of industrial size

Features

With a suitable feeding system that is designed on a case-by-case basis, molten metal can be poured inside 3D printed shapes. At the end of casting, the material of which the precasts are made slowly carbonizes (the resin component alone), allowing the metal casting to be extracted and covered with sand when solidification is complete. The resulting casting must then be deburred (removal of metal burrs at the pre-mold junctions) and finally sandblasted to ensure homogeneity of the surfaces.

Applications

-

Grids

-

Caps

-

Knobs

-

Burners

-

Wok Supports

-

Tubs

-

Distributors

-

Shut-off valves

-

Control valves

-

Pump body

-

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Diffusers

-

Circulators

-

Supports

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights

-

Racing parts

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks