Silicone rubbers

- Home

- Rapid Prototyping

- Silicone rubbers

Object

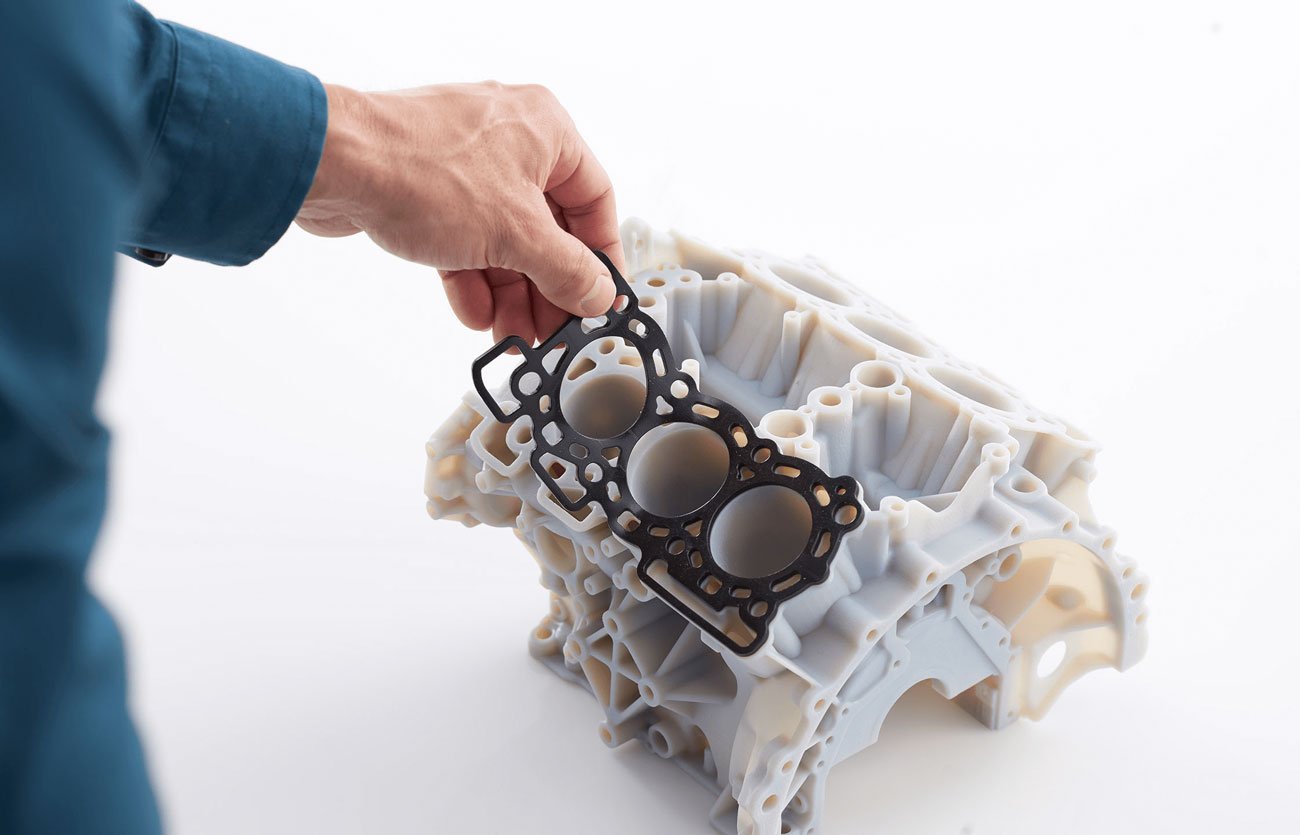

Silicone resins and rubbers

Object solutions – silicone resins and rubbers – employ liquid polymers in cartridges that allow them to simulate rigid plastics, both opaque and transparent, or rubbers in different hardnesses. They use soluble support material for the construction of the thicker undercuts.

Processing from liquid material (liquid resin) makes layering almost imperceptible, giving a really high resolution much appreciated for reproducing medium and small size parts from the world of consumer electronics or similar.

The materials are specifically formulated to maximize aesthetic appearance rather than functional compliance therefore this technique is ideal for reproducing richly detailed objects that are to serve as demos for trade shows or exhibitions (3D printing resins for demonstrations).

This solution is not suitable for functional testing where the material may fail relatively early (rigid resins may have excessive stiffness and rubbers have a limited elastic range for 3D printing).

silicone resins and rubbers

The material has a resinous texture, easy to finish but with faintly “waxy” aesthetics. High detail solution for aesthetic 3d prototyping.

-

The working range is 300 × 200 × 150 mm;

-

The definition is X-axis: 600 dpi; Y-axis: 600 dpi; Z-axis: 900 dpi;

-

The tikcness layer is 28 um for opaque materials and 16 um for transparent (clear) materials;

-

Opaque materials are ivory, gray, or black, while transparent materials need polishing to have a lenticular appearance

-

Grids

-

Caps

-

Knobs

-

Burners

-

Wok Supports

-

Tubs

-

Distributors

-

Shut-off valves

-

Control valves

-

Pump body

-

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Diffusers

-

Circulators

-

Supports

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights

-

Racing parts

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks