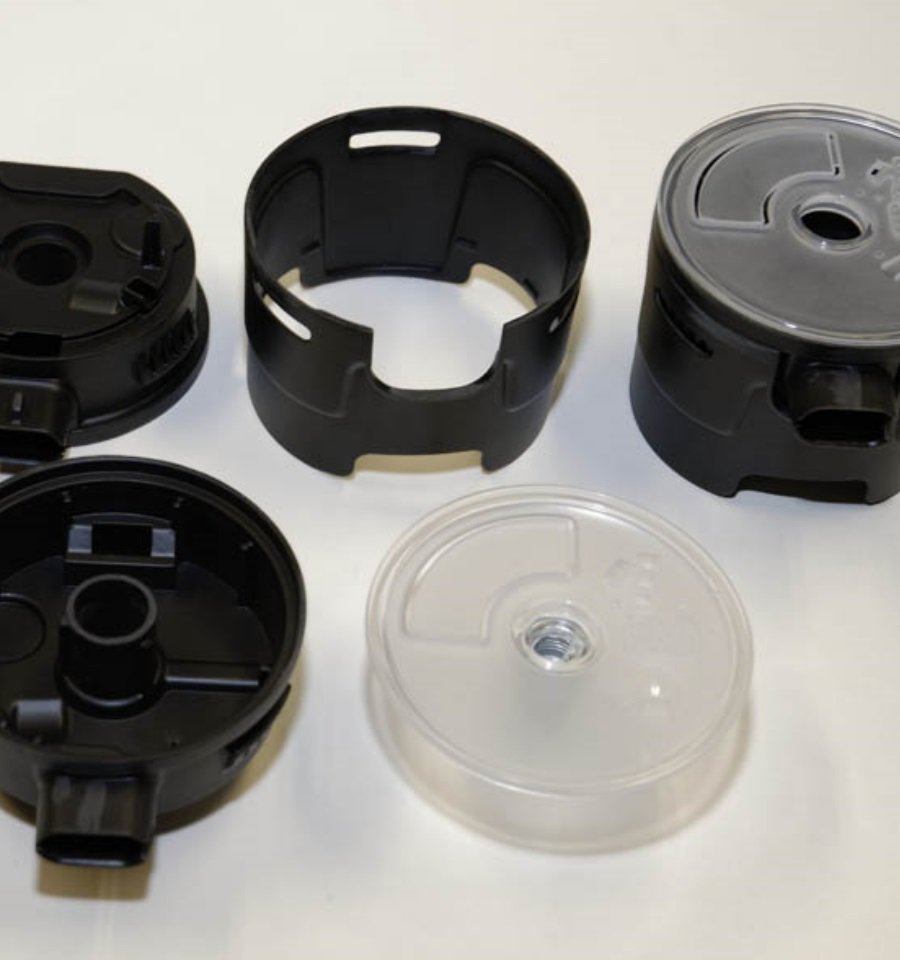

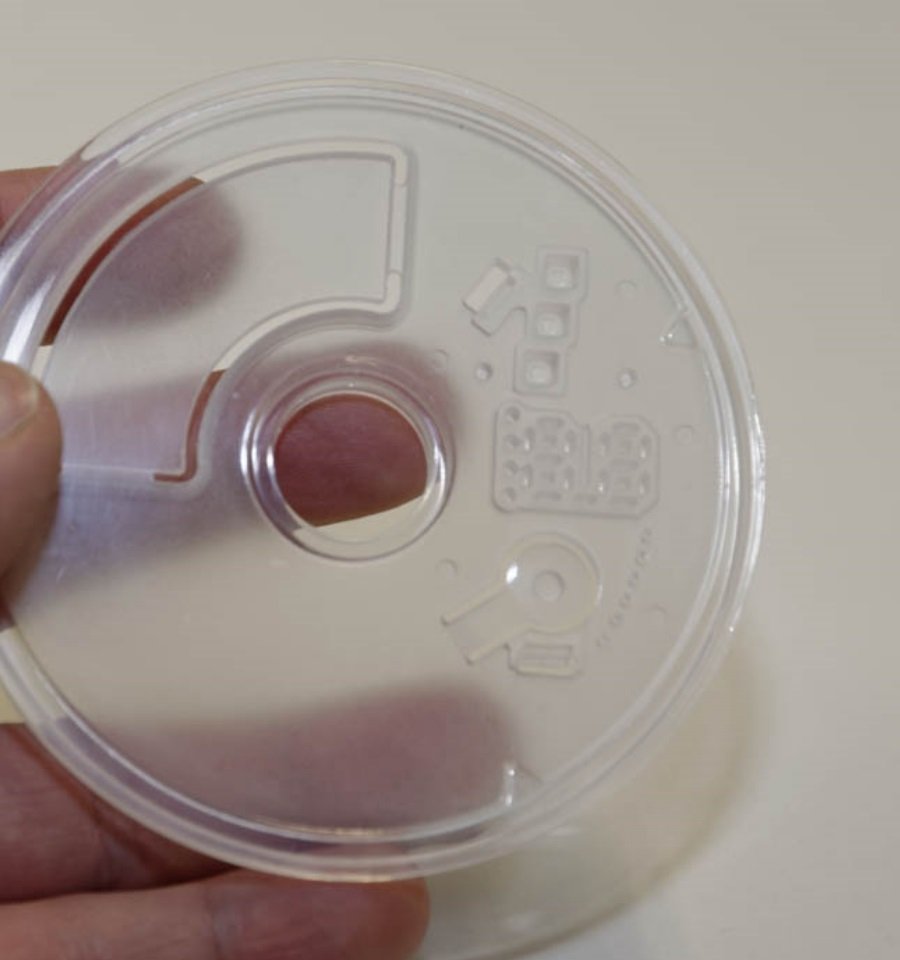

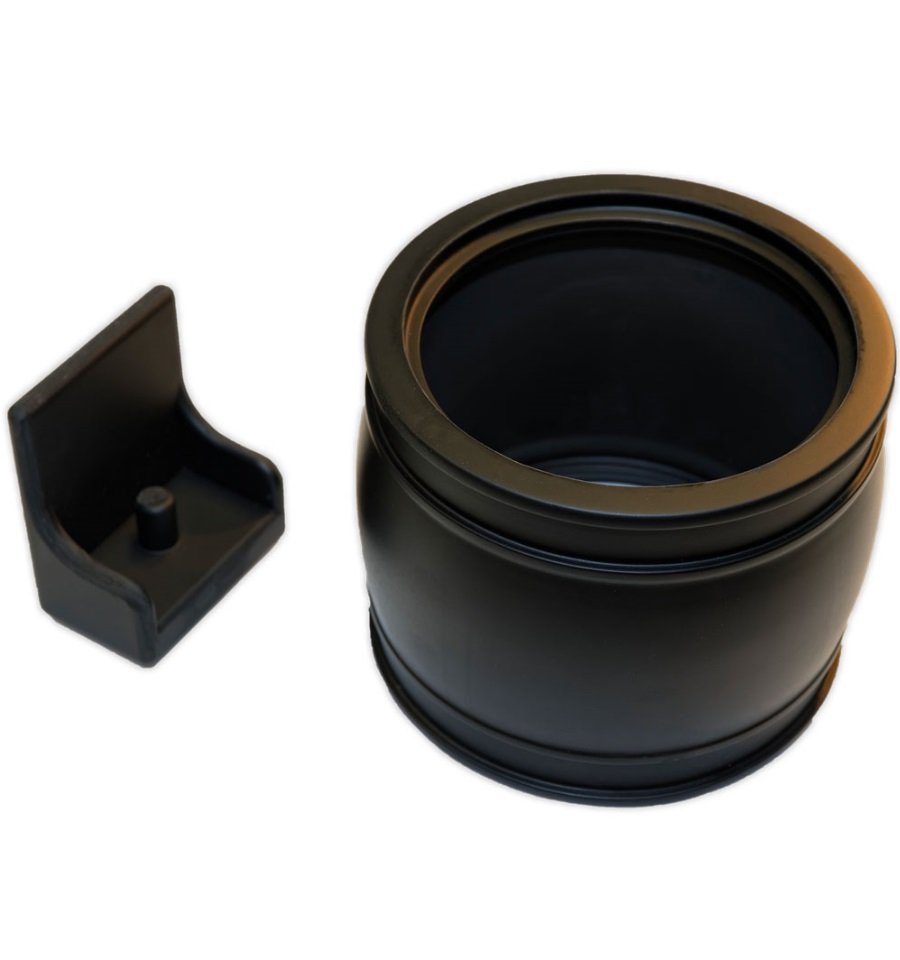

Prototypes from silicone molds for industrial pre-production uses, high functional compliance, excellent aesthetics

Two-component polyurethane resins (polyol and isocyanate) cross-link at room temperature by the addition of appropriate catalyst resulting in a stable and irreversible compound with high mechanical strength and flexibility.

Polyurethane resins are characterized by minimal linear shrinkage, rapid demolding, high impact and abrasion resistance, dimensional stability, and excellent surface finish. They withstand high temperatures and have a low dielectric constant.

Since they are very smooth and flowing products, they are appreciated in rapid prototyping and model building as they penetrate capillary into the mold ( especially when processed in a vacuum chamber ) faithfully reproducing every minute detail of the latter.

Polyurethane casting resins and silicone rubbers

The materials are characterized by a direct similarity to industrial polymer counterparts whose physical properties they seek to replicate. They are all in liquid form with the possibility of mass pigmentation.

-

ABS-like resins (PX223/HT).

-

High temperature resins (PX234/HT) with Tg 220°C.

-

PA-like resins (PX245).

-

PA-GF-like resins.

-

PP-like resin (UP5690).

-

Rubber-like (UPX8400).

See specifications

-

Grids

-

Cappellotti

-

Knobs

-

Burners

-

Wok Supports

-

Bathtubs

-

Distributors

-

Shut-off valves

-

Control valves

-

Pump body

-

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Speakers

-

Circulators

-

Supports

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights

-

Racing Components

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks