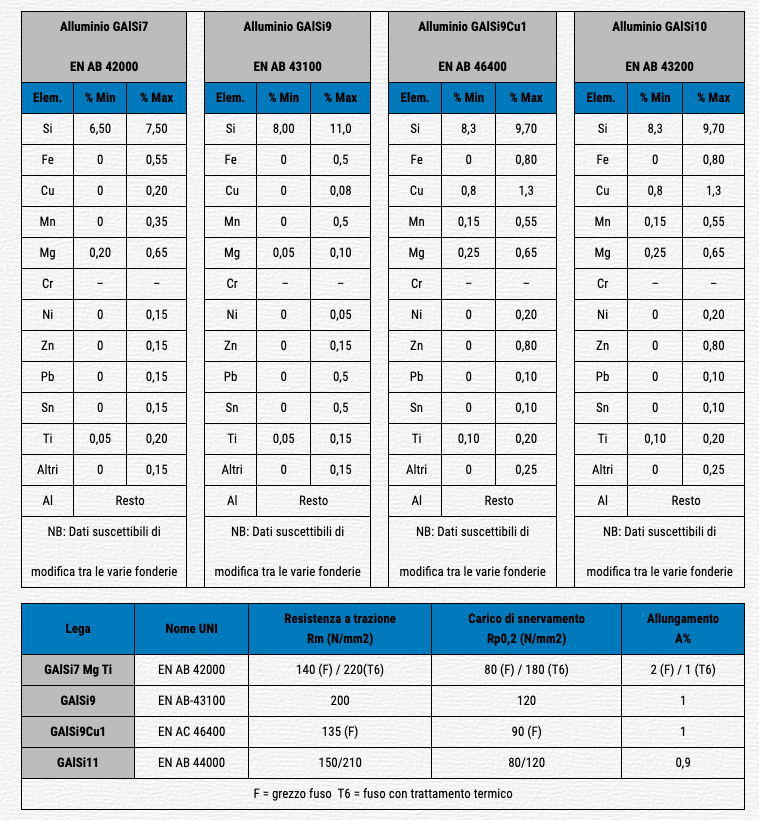

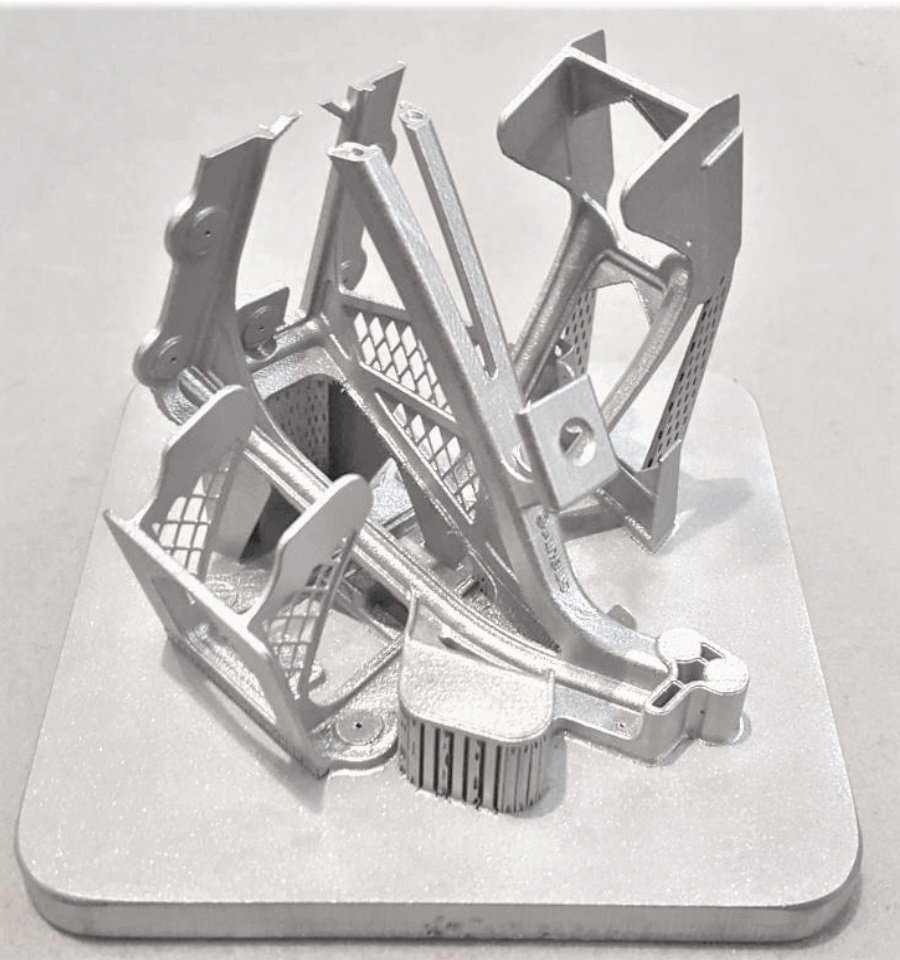

Prototypes from CNC milling, investment casting, Quick Sand Casting, DMLS sintering

Prototypes uses only alloys suitable for machining “fromcasting” (designed for gravity casting and employable with our quick sand casting processes) or machining from chips (designed for CNC milling).

Alligator effect:

-

Silicon – Yes: improves the fluidity of the cast alloy. Higher silicon content allows thinner-walled castings, however, it increases the risk of abnormal shrinkage in massive areas.

-

Copper-Cu: improves compactness and heat dissipation.

In prototyping, the combination of material and processing technique is one of the most complex choices for printing on aluminum. Running a prototype almost always requires evaluations so, for the use and consumption of engineers, average material properties obtained by prototype construction are provided. These can be used to get an idea of technical and functional compliance.

To improve machinability in aluminum rapid prototyping, it is recommended that parts undergo T6 heat treatment cycles (which also raise the overall mechanical properties).

All aluminum alloys reporting GAlSi at the beginning are:

Alloys specifically formulated for casting (G) suitable precisely for foundry processes, then specifically weighted to withstand the process of melting, part forming and subsequent solidification.

The letters AlSi indicate that it is an alloy with main constituent Aluminum and first alligant Silicon.

Foundry alloys are also recognizable by the numerical abbreviation EN AB 4xxx (4000 series).

- Aluminum Alloy GAlSi7

- Aluminum Alloy GalSi9

- Aluminum Alloy GalSi9Cu1

- Aluminum Alloy GalSi10

-

Grids

-

Caps

-

Knobs

-

Burners

-

Wok Supports

-

Tubs

-

Distributors

-

Shut-off valves

-

Control valves

-

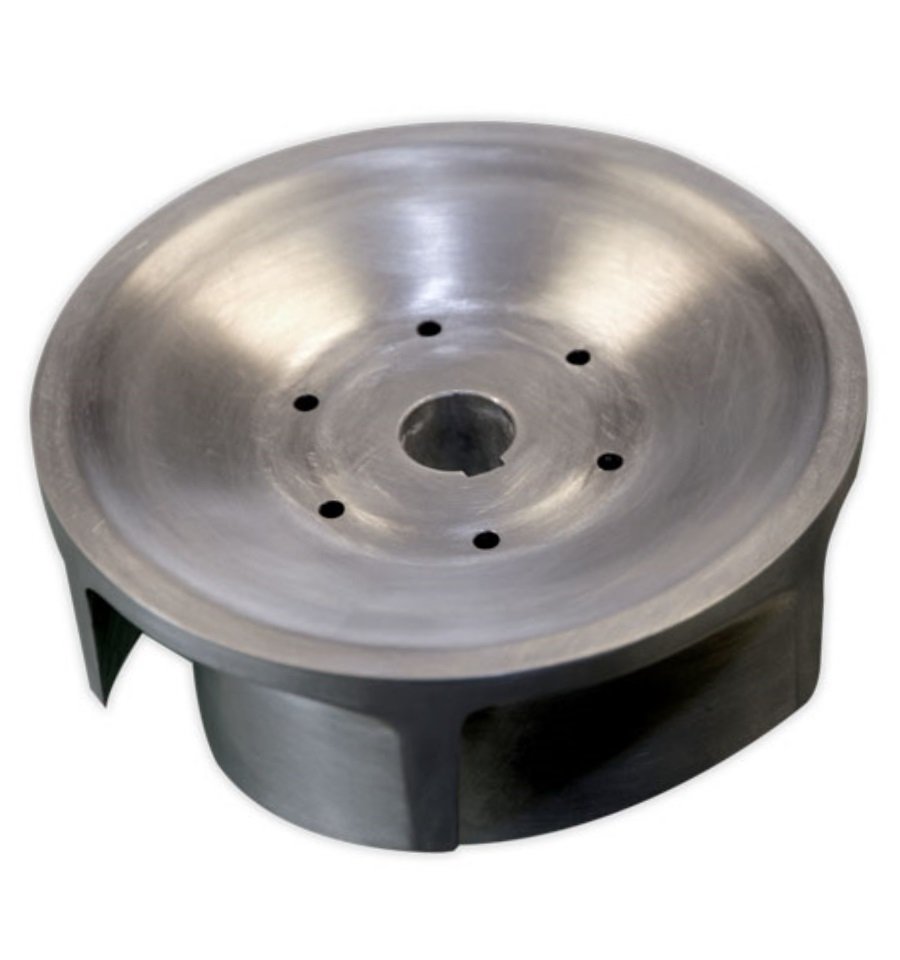

Pump body

-

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Diffusers

-

Circulators

-

Supports

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights

-

Racing parts

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks

| Elem. | % Min | % Max |

|---|---|---|

| Si | 6,5 | 7,5 |

| Fe | 0,45 | |

| Cu | 0,15 | |

| Mn | 0,35 | |

| Mg | 0,25 | 0,65 |

| Cr | - | |

| Ni | 0 | 0,15 |

| Zn | 0 | 0,15 |

| Pb | 0 | 0,15 |

| Sn | 0 | 0,05 |

| Ti | 0,05 | 0,20 |

| Individual impurities | 0,05 | |

| Global impurities | 0,15 |

| Elem. | % Min | % Max |

|---|---|---|

| Si | 9,00 | 11,0 |

| Fe | 0,45 | |

| Cu | 0,08 | |

| Mn | 0,45 | |

| Mg | 0,25 | 0,45 |

| Cr | - | |

| Ni | 0,05 | |

| Zn | 0,10 | |

| Pb | 0,05 | |

| Sn | 0,05 | |

| Ti | 0,15 | |

| Individual impurities | 0,05 | |

| Global impurities | 0,15 |

| Elem. | % Min | % Max |

|---|---|---|

| Si | 8,3 | 9,7 |

| Fe | 0 | 0,7 |

| Cu | 0,8 | 1,3 |

| Mn | 0,15 | 0,55 |

| Mg | 0,30 | 0,65 |

| Cr | - | |

| Ni | 0,20 | |

| Zn | 0,8 | |

| Pb | 0,10 | |

| Sn | 0,10 | |

| Ti | 0,10 | 0,18 |

| Individual impurities | 0,05 | |

| Global impurities | 0,25 |

| Elem. | % Min | % Max |

|---|---|---|

| Si | 9,0 | 11,0 |

| Fe | 0,55 | |

| Cu | 0,3 | |

| Mn | 0,55 | |

| Mg | 0,25 | 0,45 |

| Cr | - | |

| Ni | 0,15 | |

| Zn | 0,35 | |

| Pb | 0,10 | |

| Sn | - | |

| Ti | 0,15 | |

| Individual impurities | 0,05 | |

| Global impurities | 0,15 |

| Elem. | % Min | % Max |

|---|---|---|

| Si | 6,5 | 7,5 |

| Fe | 0,45 | |

| Cu | 0,15 | |

| Mn | 0,35 | |

| Mg | 0,25 | 0,65 |

| Cr | - | |

| Ni | 0 | 0,15 |

| Zn | 0 | 0,15 |

| Pb | 0 | 0,15 |

| Sn | 0 | 0,05 |

| Ti | 0,05 | 0,20 |

| Individual impurities | 0,05 | |

| Global impurities | 0,15 |

| Elem. | % Min | % Max |

|---|---|---|

| Si | 10,0 | 11,8 |

| Fe | 0,15 | |

| Cu | 0,03 | |

| Mn | 0,10 | |

| Mg | 0,45 | |

| Cr | - | |

| Ni | - | |

| Zn | 0,07 | |

| Pb | - | |

| Sn | - | |

| Ti | 0,15 | |

| Individual impurities | 0,03 | |

| Global impurities | 0,10 |

| Alloy | UNI name | Tensile strength Rm (N/mm2) | Yield load | Elongation A % |

|---|---|---|---|---|

| GAlSi7 Mg Ti | EN AB 42000 | 140(F) / 220(T6) | 80(F) / 180(T6) | 2 (F) / 1 (T6) |

| GAlSi9 | EN AB 43100 | 200 | 120 | 1 |

| GAlSi9Cu | EN AC 46400 | 135 (F) | 90 (F) | 1 |

| GalSi11 | EN AB 44000 | 150/210 | 80/120 | 0,9 |