- Prototypes

- July 3, 2023

The arrival of the new SLS 3D printing system(Flight HT403P-H) has put our labs in turmoil, making them capable of providing an even broader and higher quality service in the area of creating functional prototypes for industry.

In this short news item, in addition to providing some specifications about the machine, we will show in concrete terms how the printing is done.

3D powder printer

Prototypes’ choice could only fall on a professional-grade 3D printer, which allows it to sinter polymer powders and make prototypes of different shapes, sizes and materials. The innovative “open” system offers the ability to set an almost infinite number of parameters to create functional prototypes according to specific customer needs. Components that stand out for their functionality but also for their detail: the new 3D printer, in fact, has 20 percent more definition than similar machines on the market. This results in highly detailed prototypes that are immediately ready for the painting stage.

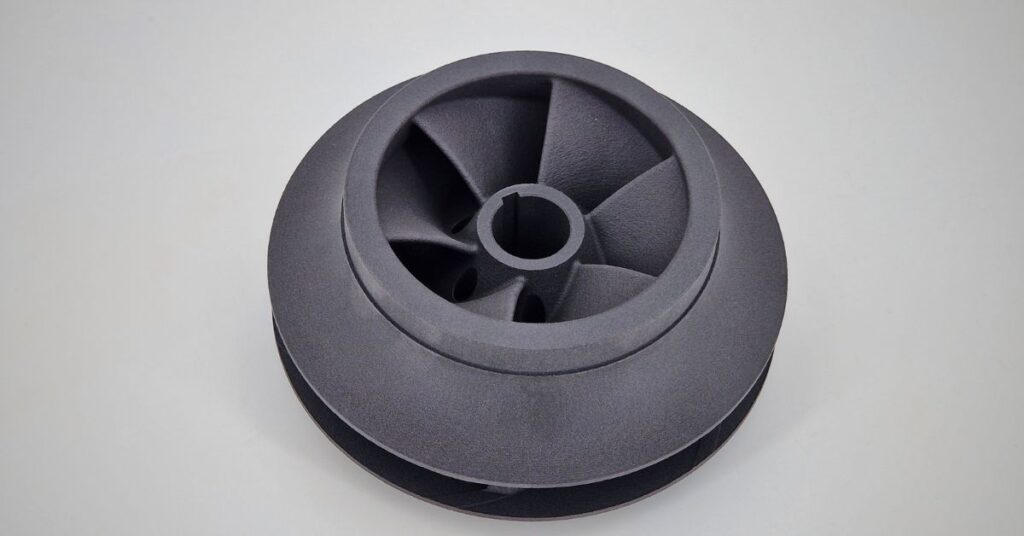

The final SLS prototype

The variety of prototypes that can be made with this printing system is wide, allowing the creation of parts of considerable size and structural complexity, in which detail and solidity coexist. In fact, the machine allows reinforcing fibers (glass, aluminum or carbon) to be added in percentages such as 15 and 30 percent.

In addition to not ovalizing circular details-which older generation machines did-the new SLS 3D printer from Prototypes is the first to be equipped with a 500W “fiber” laser, which means that the printing process is continuous, not subject to power fluctuations, and able to provide high-quality output.

Speed, detail and quality: three adjectives to describe the new SLS 3D printer for your functional sintered plastic prototypes.

Learn more about the service of

selective laser sintering

: contact us!

Prototypes Services

With Rapid Prototyping services we can make your designs a reality by producing functional parts in plastic, rubber, aluminum and cast iron in a very short time, reducing your “Time to Market” and enabling overall project cost containment.

3D CAD

Rapid Prototyping in metal and plastic

Reverse Engineering

Equipment construction

Castings supply

Mechanical design

Tridimensionalization

Parametric modeling

Applications

-

Grids

-

Caps

-

Knobs

-

Burners

-

Wok Supports

-

Tubs

-

Distributors

-

Shut-off valves

-

Control valves

-

Pump body

-

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Diffusers

-

Circulators

-

Supports

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights

-

Racing parts

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks